What do international Standards of Excellence look like in CNC Milling?

- being able to produce CNC part programmes for multiple complex parts in a short time frame with tight tolerances

- individuals must be able to master a CAD/CAM system to produce and/or edit 3D models before they use the geometry created to produce toolpath strategies and the resulting CNC programmes

- able to set the CNC machine quickly and efficiently with the greatest accuracy and create the physical component in the time limit as well as to the dimensional requirements, down to as small as +/-0.01mm

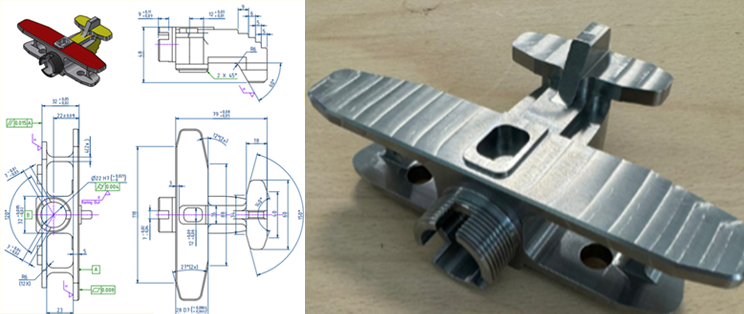

For example, the following project was modelled and programmed in 2hrs 45mins and machined, including setting the machine and tools within 4 hours. Total task time: 6 hours 45 minutes.

(Only partial drawing views are shown)